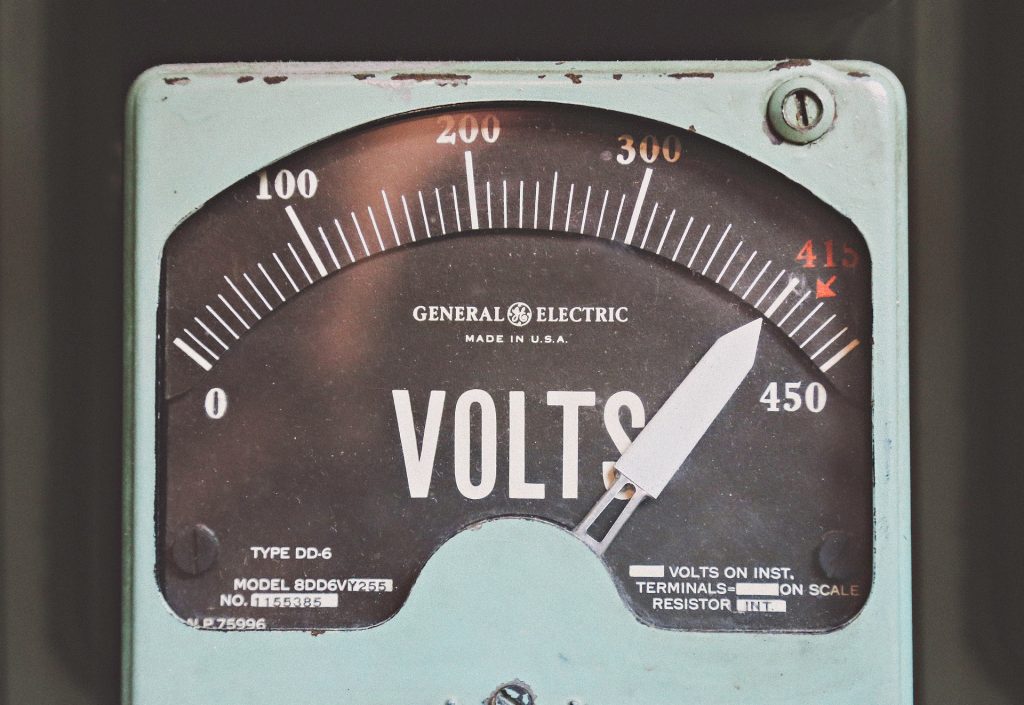

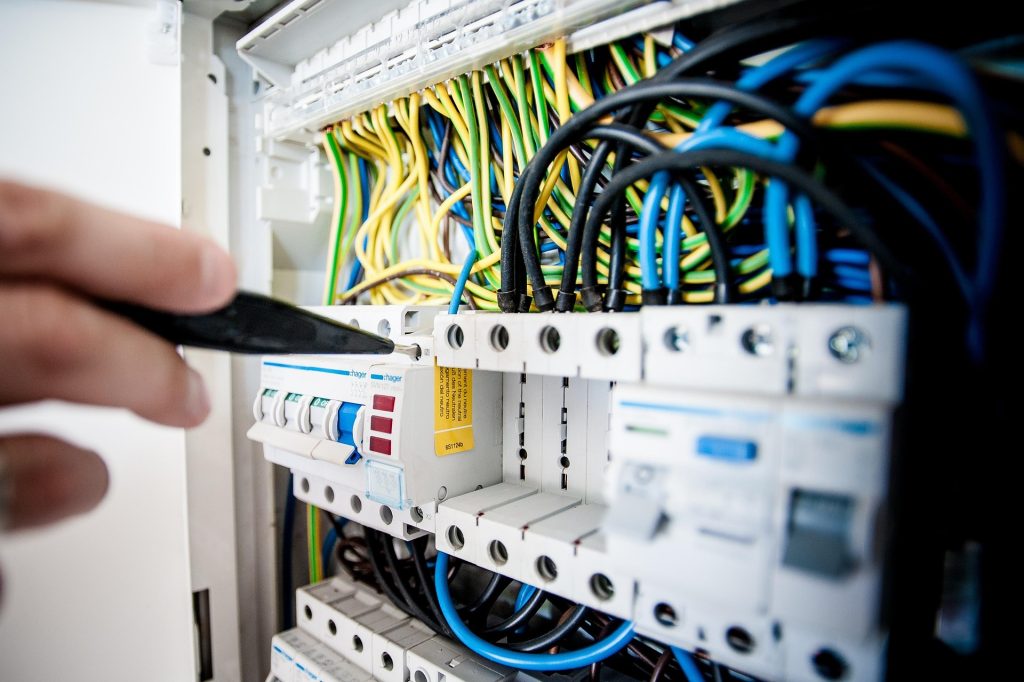

Industrial facilities rely heavily on electrical systems to power their operations, and any downtime or equipment failure can result in significant losses. Regular electrical maintenance is essential to ensure the reliability, efficiency, and safety of these systems. In this article, we’ll explore the benefits of regular electrical maintenance for industrial facilities. Benefit #1: Reduced Downtime and Increased Productivity Regular electrical maintenance helps identify potential issues before they cause equipment failure or downtime. By addressing these issues proactively, industrial facilities can minimize the risk of unexpected shutdowns, reduce downtime, and increase productivity. This, in turn, can lead to increased efficiency, reduced costs, and improved overall performance. Benefit #2: Improved Safety Electrical systems can be hazardous if not properly maintained. Regular maintenance helps identify potential safety risks, such as faulty wiring or overheating equipment, and allows for prompt corrective action. By ensuring electrical systems are safe and functioning correctly, industrial facilities can reduce the risk of electrical shock, fires, and other safety hazards. Benefit #3: Energy Efficiency and Cost Savings Regular electrical maintenance can help industrial facilities reduce their energy consumption and lower their energy bills. By identifying and addressing energy-wasting issues, such as inefficient lighting or motors, facilities can optimize their electrical systems and reduce energy waste. This can lead to significant cost savings and a reduced carbon footprint. Benefit #4: Extended Equipment Life Regular electrical maintenance can help extend the life of electrical equipment and reduce the need for premature replacements. By keeping equipment clean, lubricated, and properly maintained, industrial facilities can reduce the risk of equipment failure and prolong its lifespan. This can lead to significant cost savings and reduced waste. Benefit #5: Compliance with Regulations and Standards Industrial facilities are subject to various regulations and standards related to electrical safety and maintenance. Regular electrical maintenance helps ensure compliance with these regulations and standards, reducing the risk of fines, penalties, and reputational damage. Conclusion Regular electrical maintenance is essential for industrial facilities to ensure the reliability, efficiency, and safety of their electrical systems. By identifying potential issues before they cause downtime or equipment failure, industrial facilities can reduce costs, improve productivity, and ensure compliance with regulations and standards. If you’re looking for a reliable partner to help with your electrical maintenance needs, consider Tadoben Electrical Engineering Company. Our team of experienced engineers and technicians is dedicated to providing high-quality electrical maintenance services that meet the unique needs of industrial facilities. Get in Touch If you have any questions or would like to learn more about our electrical maintenance services, please don’t hesitate to contact us. We’re here to help you optimize your electrical systems and achieve your goals. About Tadoben Electrical Engineering Company Tadoben Electrical Engineering Company is a leading provider of electrical engineering services, including electrical maintenance, design, and installation. Our team of experienced engineers and technicians is dedicated to providing high-quality services that meet the unique needs of industrial facilities. With a focus on safety, efficiency, and customer satisfaction, we’re committed to helping our clients achieve their goals and optimize their electrical systems.